Related Questions

- How do you make and install a lightning rod?

- Can we make robots that experience emotions?

- Why can’t we put metal objects in a microwave?

- Why is it cheaper to make new plastic bottles than to recycle old ones?

- How do electricity transmission lines withstand a lifetime of exposure to the elements?

- How do touch-sensitive screens work?

What is the function of a hydraulic bypass valve?

They are crucial mechanisms for controlling the flow and pressure of liquids…

By Sarah JensenThe last thing you want to happen in the middle of a cross-country road trip — or a drive to the neighborhood market — is a brake fluid leak. Fortunately, your vehicle is equipped with a hydraulic bypass valve that redirects brake fluid if you lose pressure in your front brakes, allowing you to come to a safe stop.

“Your front brakes do the majority of the braking, so if a leak in your braking system causes a loss of pressure, you could lose all your braking power, too,” says Amos Winter, a post-doctoral research associate with the Singapore University of Technology and Design-MIT International Design Center, who will join the Department of Mechanical Engineering this summer. “The hydraulic bypass valve in the system connecting your front and rear brakes diverts the brake fluid to the rear brakes if there’s loss of pressure, so you can still stop your car.”

The bypass valve is triggered by a spring-loaded mechanism that opens when fluid pressure becomes too high or too low, Winter says. As long as the pressure is the same on both the inlet and the outlet side of the spring, the switch remains closed. But if the pressure builds up too much on one side, the spring is compressed, causing the switch to open.

It’s the same principle as the operation of a regulator on a scuba tank, says Winter. “When you suck in to breathe, you’re lowering the pressure in the mouthpiece,” he explains. “That acts on a diaphragm that opens a valve to let air flow from the tank into your lungs. When you blow out, it closes the valve and allows the air to flow out into the water.”

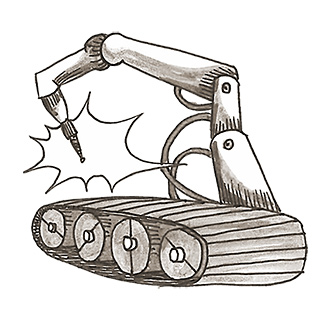

Bypass valves are important in any system through which water or oil is pumped to maintain an even pressure and keep the system operating. Construction equipment in particular relies on bypass valves to relieve pressure build-up. “If you’re operating a bucket loader,” Winter explains, “you open a valve that pumps oil into the arm that lifts a piece of concrete. You shut that valve off when you’re through, but the pump is still running and trying to pump fluid into a closed valve.” With nowhere to flow, the oil could create too much pressure, leading to a stalled engine — or an explosion. But before that happens, the bypass valve opens to vent the pressure and divert the oil back to the pump’s reservoir.

Engineering areas such as machine and aircraft design and fluid dynamics employ bypass valve technology, as do Winter’s research concentrations, mobility aids for use in harsh environments and undersea burrowing technologies. “Bypass valves are basically there to vent pressure,” he says. “Hydraulic systems operate at 2,000 pounds per square inch, and you don’t want something like that to blow up.”

Thanks to 30-year-old Matt Miller from Derby, England, for this question.

Posted: March 27, 2012